When you hear about services like Yumpingo the focus is always on the technology and the results, but the real value is how people use it. The reason our clients see such significant business results is because Yumpingo empowers people to implement a culture of continuous improvement into their businesses.

Whenever continuous improvement is introduced to new sectors they give the people doing it a huge advantage:

Kaizen

Kaizen is a Japanese term meaning ‘changes for the better’, or ‘continuous improvement’.

It’s a business philosophy that focuses on making numerous incremental changes to improve operations, customer satisfaction and business results.

It was developed in the Japanese automotive industry during the 1960s.

It enabled companies like Toyota to rapidly build a reputation for high quality manufacturing, mechanical reliability and competitive value, giving them a significant market advantage.

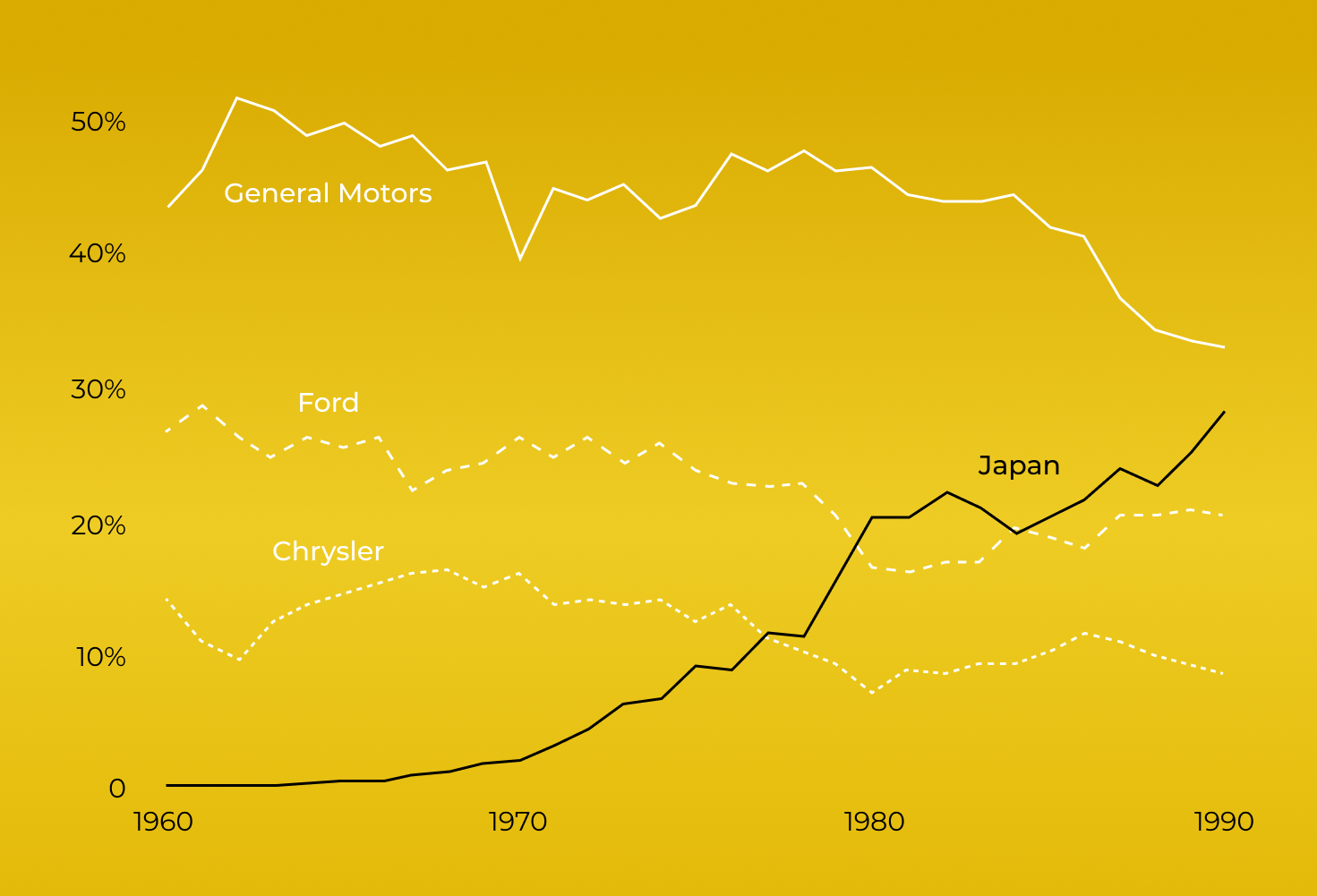

In 1970, Japanese cars only had a 1.4% market share in the U.S.

By 1979 it had surged to 21%.

And today they account for 40%.

It took decades for the other manufacturers to catch up, implement similar processes and be able to compete again.

Marginal Gains

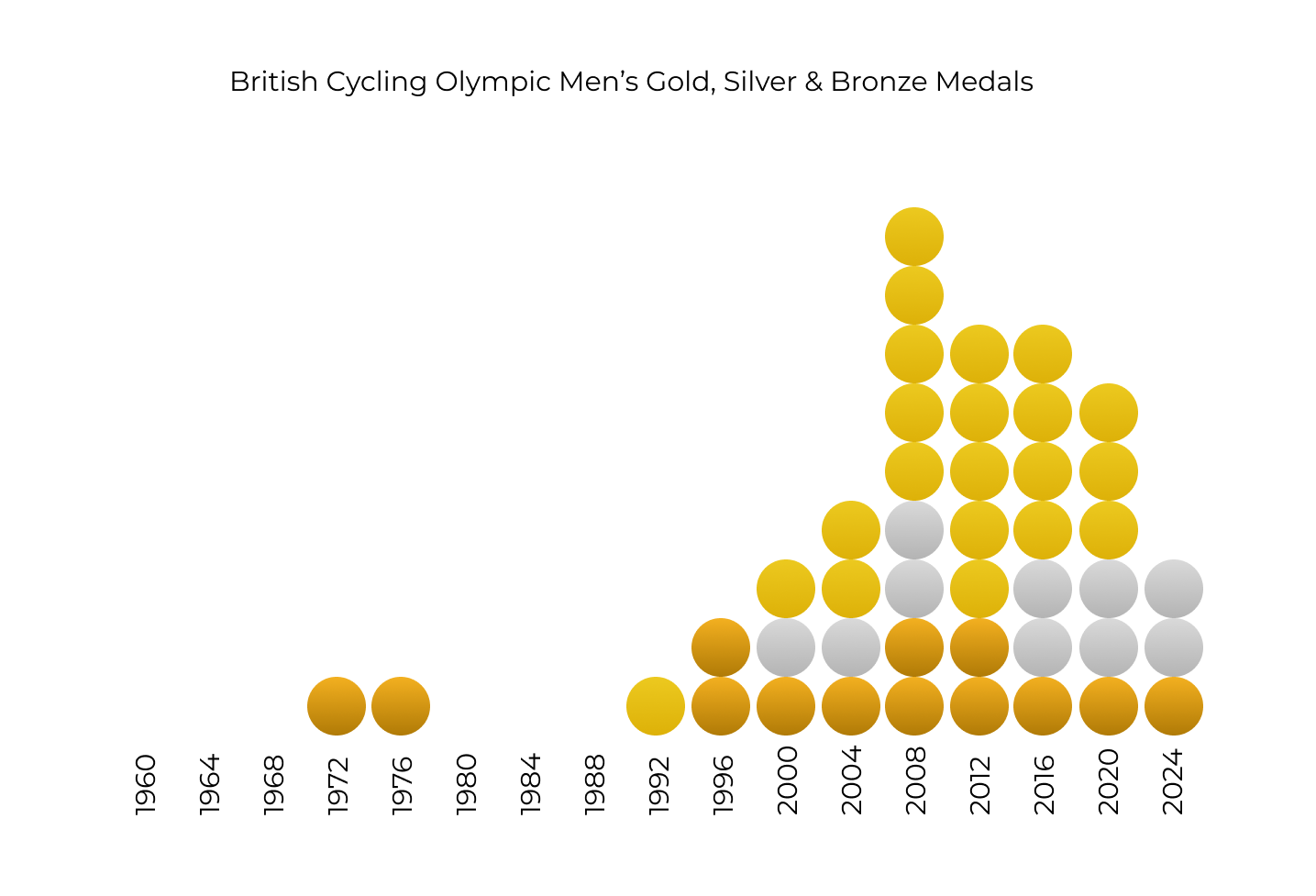

Britain was not good at cycling.

The British cycling team had won a couple of gold medals in the 1908 London Olympics, and then one solitary tandem racing gold in 1920.

After that; 72 years of nothing.

Then out of the blue, in the 1998 Barcelona Olympics, Chris Boardman jumped on a science fiction Lotus bike and won gold in the track pursuit.

That was a quantum leap rather than continuous improvement and very quickly bikes like that were banned.

But while the rest of the world went back to the comfort of doing the same things, British Cycling and their new Performance Director David Brailsford, saw an opportunity.

As they couldn’t wholly reinvent the bicycle they decided to focus on improving every other thing they possibly could, calling their version of continuous improvement “marginal gains”.

"The whole principle came from the idea that if you broke down everything you could think of that goes into riding a bike, and then improved it by 1%, you will get a significant increase when you put them all together.” - David Brailsford

They relentlessly improved every element of the bikes, the aerodynamics, the clothing, the food the team ate, the training and the racing strategy.

British Cycling suddenly became the dominant force over the next few Olympics, winning 19 gold medals in the men's events.

Following their success, the same people set up Team Sky and won 7 Tour de France titles in 8 years, in a race that no British rider or team had won in the previous 100 years!

It took 20 years before other nations and professional teams were able to catch-up and start effectively using continuous improvement themselves.

Continuous Actions Process

Sports like track cycling operate in a kind learning environment, but it still took almost 40 years before someone started implementing continuous improvement effectively.

Kind learning environments: Immediate, accurate, and abundant feedback, in situations with consistent rules

Hospitality very much operates in a wicked learning environment.

Wicked learning environments: Delayed, distorted and limited feedback, in complex situations

Restaurant groups are complex businesses with historically poor feedback such as one mystery dining review a month.

To be able to implement continuous improvement effectively in this environment requires a significant shift in the quality of feedback.

You need to have:

- High quantity and granular menu item customer feedback, to accurately highlight real issues that need to be addressed.

- Systems that highlight and prioritise actions to guide stretched frontline teams.

- Processes that highlight strategic needs, to enable central teams to make informed decisions, drive consistency and develop their offering.

- Accurate and real-time customer satisfaction tracking to measure success, gauge the effectiveness of improvement efforts and sustain momentum.

This is the problem that Yumpingo and the Continuous Actions Process (CAP) was designed to solve, enabling the complex business of restaurants to benefit from the proven benefits of continuous improvement.

And restaurants that implement CAP are gaining an advantage and seeing significant results; increasing guest satisfaction and revenue growth.

“To improve is to change; to be perfect is to change often.” - Winston Churchill.